21/01/2020

Whether you like it or not, the UK is a windy place. It is therefore not surprising that wind accounted for more than 50% of the electricity generated from renewable energy sources in 2019[1]. Modern energy generation wind turbines can come in many forms, in this blog I will discuss vertical axis wind turbines (VAWTs) which are becoming a larger part of the wind renewable energy market.

The most well-known wind turbines in the market are horizontal axis wind turbines (HAWTs). These turbines operate in a similar manner to traditional windmills. They require vast spaces with ample wind in order to function properly. Turbines of this type are produced by wind power giants such as Vestas, MHI Vestas and General Electric and can have an average capacity of over 3.5 MW. However they cannot be located close to towns or cities since they are large, loud and can be dangerous to aircraft.

Vertical axis wind turbines are an alternative type of turbine that have the potential to bring wind generation closer to home. Vertical turbines operate using a rotor shaft that is perpendicular to the wind and vertical from the ground. The blades are set apart from the shaft and are also perpendicular to the wind. The rotors are shaped so that they spin around the central shaft as wind passes.

Advantages of vertical axis wind turbines

Compared to typical horizontal axis wind turbines, vertical axis wind turbines are omnidirectional so they do not need to track the wind direction this can result in fewer mechanical components and therefore easier maintenance effort or costs.

Vertical wind turbines are also more compact and can be placed closer together. This is where vertical turbines blow away the competition. Research has shown that despite individual vertical wind turbines being less efficient than typical individual horizontal turbines, using a tighter spacing of counter-rotating turbines allows vertical wind turbine farms to have higher power densities.

Typical horizontal turbines on the other hand must be spaced far apart because the wake generated by one turbine can interfere aerodynamically with neighbouring turbines. For example, horizontal turbines can produce 2-3 W per square metre, but tests with vertical wind turbine farms show a possible production of 30 W per square metre[2].

The gearbox of a vertical axis wind turbine can be placed at the base of the turbine in line with the turbine axis and also on the ground. This configuration reduces loads on the wind turbine tower and allows easier maintenance of the turbine.

Disadvantages of vertical axis wind turbines

Since the blades of vertical axis wind turbines are subject to widely varying forces they can be prone to fatigue. This issue has mostly been resolved with the use of modern composite materials and different designs.

Vertical axis wind turbines are also more prone to dynamic stall because the movement of the turbine produces large variations in the angle of attack on the blades during each revolution. However alternative designs such as helical rotor blades have been shown to reduce the chances of stalling.

Patent activity for vertical axis wind turbines

One of the earliest patents filed for a vertical wind turbine was a French and US application filed by Georges Darrieus in France in 1926 (link) and in the US 1931 respectively (link). These applications coined the name “Darrieus” for the type of vertical axis wind turbine which comprise several bowed rotors. Since then various types of vertical axis wind turbine have been developed and patented. The main designs include Darrieus, Savonius, Giromill and Gorlov turbines. These range from straight rotors to helical rotors and each design has specific advantages.

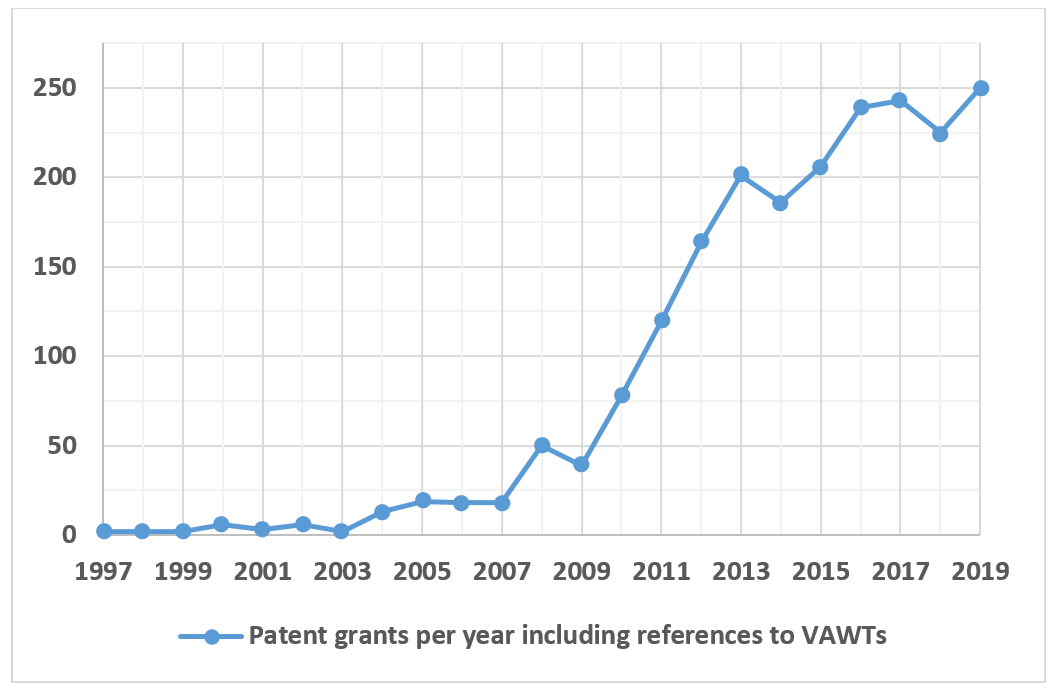

In the last 10 years there has been a surge in the number of patents granted relating to vertical axis wind turbines. From 2009 to 2019 there has been an increase of more than 500%. Top applicants include wind power giants such as Vestas and General Electric who combined have more than 200 vertical wind turbines patents between them.

An increase in patent activity gives a good indication of the direction of the industry. With increased adoption of vertical wind turbine technology from large wind generation companies such as MHI Vestas and General Electric we may also see small and mid-sized companies invest in development in the coming years. More importantly, we may see increased use of vertical wind turbines in areas that are unused and would otherwise be unsuitable for horizontal turbines.

As discussed, individual vertical turbines may not be able to compete with individual horizontal turbines, however they may be the answer to a more accessible source of renewable wind energy that can be used closer to towns and cities. There are many conceivable applications for vertical turbines where horizontal turbines would not be suitable. For example, placing wind turbines in close proximity to major roadways would simultaneously harness natural wind and also gusts produced by moving vehicles. These turbines could be mounted on lamp posts or overhead gantries to avoid low level traffic. Vertical axis turbines could also be fitted on top of most city buildings without risk to air traffic due to their small rotor span.

Vertical axis wind turbine related inventions are prime candidates for patent protection. Unlike traditional horizontal axis wind turbines, vertical turbines have received relatively little research and development which means there is great potential for further innovation.

References

[1] Digest of UK Energy Statistics (DUKES) 2019 (https://www.gov.uk/government/statistics/digest-of-uk-energy-statistics-dukes-2019)

[2] J. O. Dabiri, “Potential Order-of-Magnitude Enhancement of Wind Farm Power Density via Counter-Rotating Vertical-Axis Wind Turbine Arrays,” J. Renew. Sustain. Energy 3, 043104 (2011).

This article is for general information only. Its content is not a statement of the law on any subject and does not constitute advice. Please contact Reddie & Grose LLP for advice before taking any action in reliance on it.